신에너지 자동차(NEV) 산업의 급속한 발전과 국가 차원의 "이중 탄소" 목표 추진으로 에너지 소비 감소, 배출가스 감축, 전기차 주행거리 연장은 자동차 혁신의 핵심 과제가 되었습니다. 차량 무게를 10% 줄이면 연료 소비를 다음과 같이 줄일 수 있습니다. 6%~8% 그리고 전기차 주행거리를 연장합니다 5%~10% . 그러므로, 자동차 경량화 이는 에너지 효율과 주행거리 성능을 향상시키는 가장 효과적인 전략 중 하나입니다.

자동차 경량화에서 복합재료의 역할

복합재료 높은 비강도, 낮은 밀도, 뛰어난 강성 및 강력한 설계 유연성으로 잘 알려진 이 소재들은 현대 자동차에서 기존 금속을 점차 대체하고 있습니다. 이 소재들은 다양한 분야에 널리 사용됩니다. 차체 구조, 섀시 시스템, 내부 인테리어, 파워트레인 부품 및 전기차 배터리 시스템 이는 산업이 효율적이고 저탄소이며 지속 가능한 제조 패러다임으로 전환하는 속도를 가속화합니다.

경량화의 장점

일반적인 자동차용 복합재료(다음 포함) CFRP(탄소섬유 복합재) , GFRP(유리섬유 복합재) , 그리고 현무암 섬유 복합재 —상당한 이점을 제공합니다:

- 밀도만 강철의 1/4~1/3 그리고 알루미늄 2/3

- 특정 강도 강철보다 5~6배 더 높습니다. 그리고 알루미늄보다 3~4배 더 높음

- 부품 무게 감소: 30%~60%

- 차량 총 중량 감소: 10%~30%

복합재료는 또한 뛰어난 성능을 제공합니다. 피로 저항성, 부식 저항성, 진동 감쇠 및 NVH 성능 유지 보수 비용을 절감하고 주행 편의성을 향상시킵니다.

차량 주요 시스템의 경량화 기술 적용

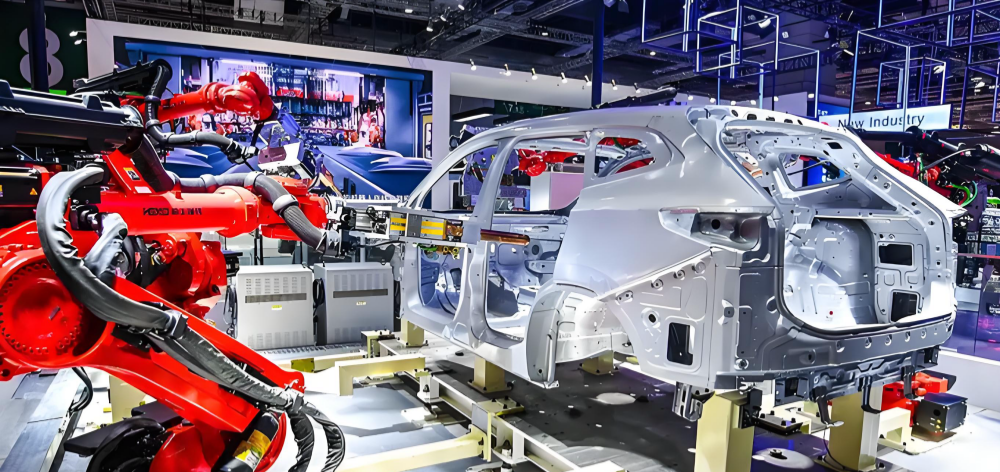

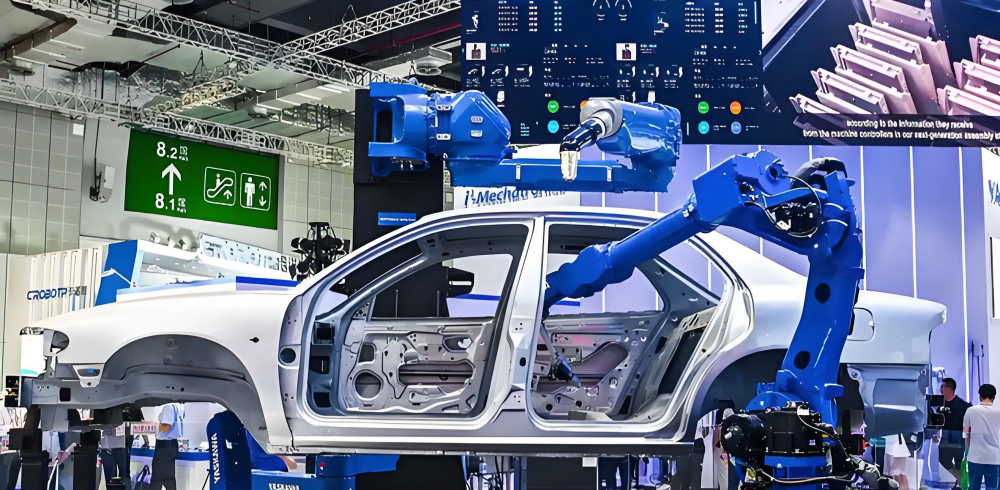

차량 차체 및 구조 부품

구조적 요소로는 다음과 같은 것들이 있습니다. 차체 프레임, 문, 보닛, 트렁크 덮개 CFRP 또는 GFRP로 성형할 수 있으며, 35%~50% 질량 감소 공기역학 및 강성을 향상시키면서. 예: CFRP 차체를 적용한 NEV는 다음과 같은 성과를 달성했습니다. 총 중량 22% 감소 그리고 주행 가능 거리 18% 증가 .

섀시 및 파워트레인 경량화

복합 소재 서스펜션 암, 드라이브 샤프트 및 휠 허브는 현가하질량을 줄이고 동적 성능을 향상시킵니다. 탄소 섬유 드라이브 샤프트는 다음과 같은 이점을 제공할 수 있습니다. 40% 무게 감소 그리고 5%~8% 더 높은 전송 효율 .

전기차 배터리 팩 경량화

배터리 팩 하우징은 다음으로 만들어졌습니다. 유리섬유 강화 에폭시 복합재료 제안 금액 50% 무게 감소 강철 대비 우수한 난연성, 내충격성 및 방수성을 제공합니다. 복합 소재 배터리 트레이와 결합하여 시스템 에너지 소비를 줄이고 전기차의 주행 거리를 늘립니다.

내부 경량화

복합재료는 널리 사용됩니다. 시트 프레임, 계기판 캐리어, 도어 내부 모듈 달성하다 25%~40% 무게 감소 복합 소재 시트 프레임은 다음과 같은 특징을 가질 수 있습니다. 50% 더 가벼워짐 강철보다 PP-GF 계기판 캐리어는 더 높은 곳에 도달할 수 있습니다. 30% 더 가벼워짐 무게 증가 및 방음 성능 향상.

미래 동향: 비용 절감 및 첨단 제조

재료 기술 발전

하이브리드 섬유, 변성 수지, 나노 필러, 바이오 기반/재활용 가능 복합재료와 같은 혁신 기술은 성능을 향상시키면서 비용을 절감합니다.

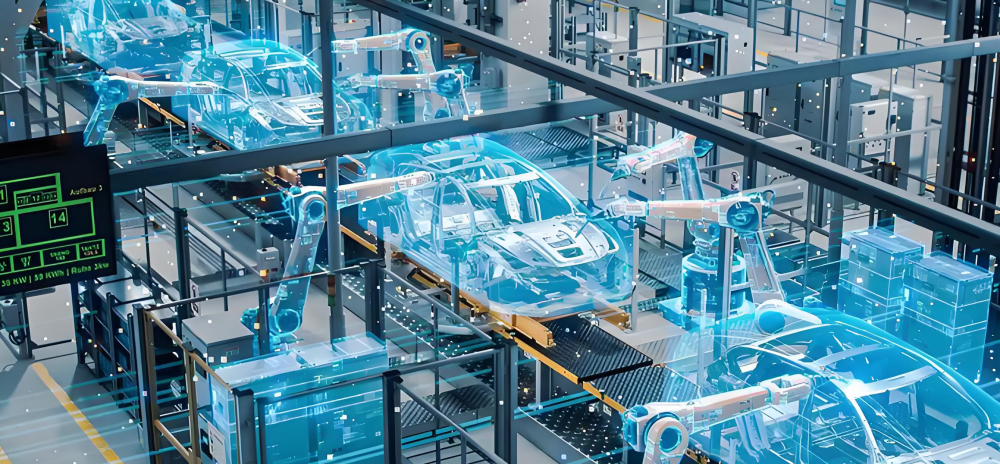

첨단 처리 기술

차세대 성형 및 가공 기술인 HP-RTM(고압 수지 이송 성형), AFP(자동 섬유 배치) 및 3D 복합재 프린팅은 복합재 부품의 효율적인 대량 생산을 가능하게 합니다.

비용 하락 추세

복합재료 비용은 감소할 것으로 예상됩니다. 향후 5~10년 내에 30~50% 이를 통해 중형 및 보급형 차량에 더욱 폭넓게 적용할 수 있습니다. 스마트 센싱 및 디지털 트윈 기술과 결합하여 전 생애주기 모니터링을 통해 신뢰성과 안전성을 더욱 향상시킬 수 있습니다.

결론

복합 소재는 자동차 경량화의 핵심 동력으로 자리 잡았습니다. 복합재료의 대규모 도입은 자동차 제조 방식을 혁신하고 있으며, 에너지 효율성, 구조적 성능 및 전기차 주행 거리를 향상시키고 있습니다. 기술이 발전함에 따라 복합재료는 고급화, 저탄소화 및 지속 가능한 개발을 향한 산업의 전환을 지속적으로 주도하며, 전 세계적인 탄소 중립 및 감축 목표 달성을 지원할 것입니다.

이메일

이메일 한국의

한국의 English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 中文

中文