-

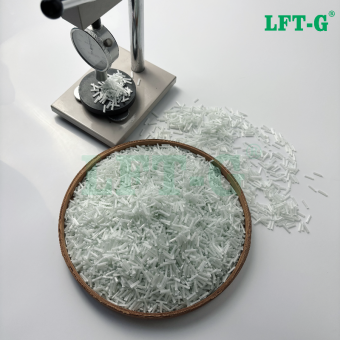

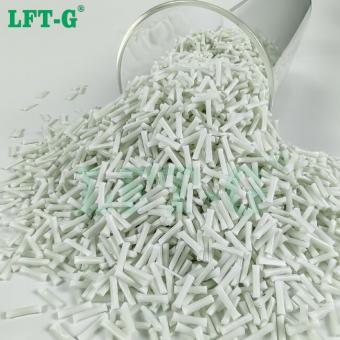

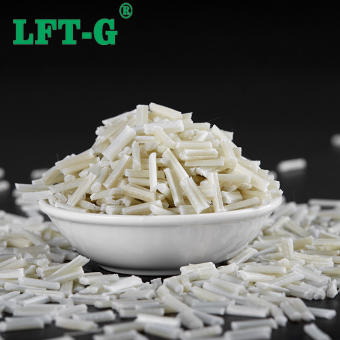

PBT 충전 긴 유리 섬유 LGF 사출 등급 복합 고품질 천연 색상PBT-LGF 폴리부탄디올 테레프탈레이트(PBT)는 높은 결정화도, 신속한 프로토타이핑, 내후성, 낮은 마찰 계수, 높은 열 변형 온도, 우수한 전기적 특성, 우수한 기계적 특성, 내피로성과 같은 우수한 종합 특성을 가지며 초음파 용접이 가능합니다. 그러나 노치 충격 강도가 낮고 성형 수축률이 크며 가수 분해 저항이 좋지 않고 유리 섬유 보강 후 할로겐화 탄화수소에 의해 침식되기 쉽습니다. 우수한 종합 성능으로 PBT는 전자 및 전기 제품, 자동차 산업, 기계, 기기 및 가전 제품 및 기타 분야에서 널리 사용됩니다. 일반적인 문제 및 해결 방법 Glass fiber reinforced PBT material warps easily Reasons: Warping is the result of uneven shrinkage of the material. The warping of the product can be caused by the orientation and crystallization of the components in the material, the improper technological conditions used in the injection molding, the wrong shape and position of the gate in the mold design, and the uneven thickness of the wall in the product design. The warping of PBT/GF composites is mainly due to the fact that the orientation of the glass fiber in the flow direction restricts the shrinkage of the resin, and the induced crystallization of PBT around the glass fiber strengthens this effect, making the longitudinal (flow direction) shrinkage of the product less than the transverse (perpendicular to the flow direction). This uneven shrinkage leads to the warping of PBT/GF composites. Solution: 1. Add minerals and use the shape symmetry of mineral fillers to reduce the anisotropy caused by the glass fiber orientation; 2. Add amorphous materials to reduce the crystallinity of PBT and reduce the uneven shrinkage caused by crystallization, such AS ASA or AS, but they have poor compatibility with PBT, so appropriate compatibilizers need to be added; 3. Adjust injection molding process, such as increasing mold temperature and increasing injection cycle appropriately. Glass fiber reinforced PBT surface floating fiber problem Reasons: The causes of floating fiber are more complex, in short, there are mainly the following aspects 1. The compatibility of PBT and glass fiber is very poor, resulting in the two can not effectively bond together; 2. The viscosity of PBT and glass fiber is very different, resulting in a tendency of separation between the two in the flow process. When the separation effect is greater than the adhesive force, the separation will occur, and the glass fiber will float to the outer layer and leak out; 3. The existence of shear force will not only lead to local viscosity differences, but also destroy the interface layer melt viscosity on the glass fiber surface, the smaller the interface layer is damaged, the smaller the bonding force on the glass fiber. When the viscosity is low to a certain degree, the glass fiber will get rid of the PBT resin matrix and gradually accumulate to the surface and expose. 4. Influence of mold temperature. Due to the low temperature of the mold surface, the glass fiber with light weight and fast condensation is frozen instantaneously. If it is not fully surrounded by melt in time, it will be exposed and form "floating fiber". Solution: 1) Add compatibilizers, dispersants and lubricants to improve the floating fiber problem. For example, the use of special surface treatment of glass fiber, or adding compatibilizers (such as: SOG, a well-flowing PBT modified compatibilizer) through the "bridge" effect, increase the adhesion of PBT and glass fiber. 2) Optimize the molding process to improve the floating fiber problem. Higher injection molding temperature and mold temperature, larger injection molding pressure and back pressure, faster injection molding speed, lower screw speed, can improve the floating fiber problem to a certain extent. The glass fiber reinforced PBT injection molding process is easy to produce more mold scale Reasons: The formation of mold scale is caused by the high content of small molecules or the poor thermal stability of materials. Compared with other materials, PBT is easy to generate mold scale due to its oligomer and small molecule residue rate usually in the range of 1%-3%. And after the introduction of glass fiber, more obvious. This will lead to the continuous processing process, the need to clean the mold regularly, resulting in low production efficiency. Solution: 1) Reduce the amount of small molecule additives (such as lubricant, coupling agent, etc.), try to choose polymer additives; 2) Improve the thermal stability of PBT and reduce the small molecular products produced by thermal degradation during processing; PBT Application Widely used in machinery, electronic and electrical, automotive industry and household appliances and other fields. Related information Colour Length Sample Package Port of Loading Shiping time Natural 5mm~12mm Available 25kg/bag Xiamen Port 7더보기

이메일

이메일 한국의

한국의 English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 中文

中文