장섬유 열가소성 수지(LFT) 기술은 계속 발전하고 있습니다. 자동차 응용 분야가 시장 지배력을 유지하는 동안 다른 산업 분야는 경량 및 고강도라는 약속에 점점 더 매력을 느끼고 있습니다. 예를 들어 LFT PP 화합물은 금속에 대한 저렴한 대안과 고비용의 기술 엔지니어링 폴리머를 제공할 수 있습니다.

LFT PP Comp의 지속적인 침투자동차 부문의 운

2021년 9월 AMI Consulting에서 발표한 보고서에 따르면 PP 시장 침투율은 계속해서 증가하고 있습니다. 이 보고서는 세분화된 형태의 LFT PP(LDT-G) 및 직접 인라인 복합 LFT PP(LDT-D)의 사용을 정량화하고 전 세계 사용량을 추적합니다. LFT PP는 자동차 프런트 엔드 마운트, 대시보드 마운트, 도어 패널, 콘솔, 페달, 언더바디 실드 및 기타 여러 자동차 애플리케이션에 널리 사용됩니다. 이러한 응용 분야의 한 가지 특징은 LFT PP가 강철을 대체하여 무게를 줄이거나 더 비싼 엔지니어링 플라스틱을 대체한다는 것입니다.

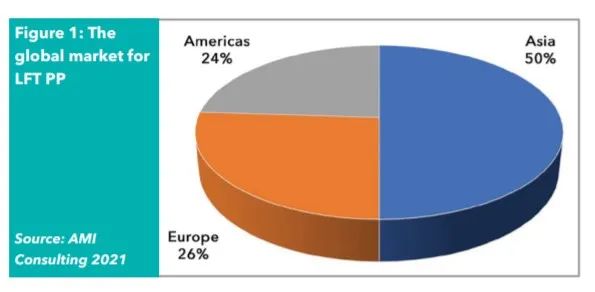

AMI Consulting은 LFT PP가 2025년까지 강력한 성장세를 유지할 것으로 예측합니다. 성장률은 애플리케이션 부문, 자동차 OEM 및 지리적 시장에 따라 다르지만. 과거에는 유럽이 LFT 판매의 선두 주자였지만 상황이 바뀌었습니다. 보고서에 따르면 아시아는 2020년 전 세계 LFT PP 수요의 50%를 차지하며, 유럽은 26%, 미주는 24%를 차지합니다(표 1).

표 1: 지난 20년간 글로벌 LFT PP 시장 분포

가장 빠르게 성장하는 응용 분야 중 하나는 모든 금속에서 금속이 거의 없는 디자인에 이르는 자동차 트렁크용 리프트 도어입니다. 금속이 없는 디자인에서 LFT PP는 구조적 강도를 제공하는 데 사용되며 고성능 PP로 보완되어 도장 가능한 외피를 제공합니다. 가장 까다로운 응용 분야에서 구조 내의 LFT PP 요소가 노출되므로 우수한 미적 마감이 필요합니다. 플라스틱 리프트 도어는 무게를 줄이는 새로운 방법으로서 전기 자동차 제조업체에게 특히 가치가 있습니다.

The shift to electric and hybrid vehicles, while threatening some existing polymer applications, is also creating new opportunities for LFT PP as designers are rethinking concepts and adopting new approaches. The report cites the example of Tesla's "frunk" -- a back-up or storage compartment located at the front. This would make use of space in the front of the vehicle for storage, but would need to be designed with the ability of a traditional car's front end to absorb the impact of a crash.

The strong interest in LFT materials from various industries is confirmed by RTP Inc., which offers a wide range of LFT materials. "Replacement metal parts or over-engineered short fiberglass compounds continue to be major growth opportunities," said Zach Halverson, Manager of the company's structured products business. For example, long fiber polypropylene compounds can often successfully replace short glass fiber polyamide compounds to provide a lower cost and lower density solution." Long fiber technology in engineering and high performance based polymers such as PEEK, PPA, PEI and PPS, these combine the desired mechanical and thermal properties of the polymer with the added benefit of long fibre reinforcement. They are said to be a good alternative to metals in particularly demanding environments, such as in the oil and gas industry, where other materials cannot meet demand (Table 2)

Table 2: Long glass fiber reinforced polymer compounds with tensile strength range of 40%.

Halverson said the automotive industry remains the largest consumer of long-fiber thermoplastics, and any changes in the industry will affect its use.

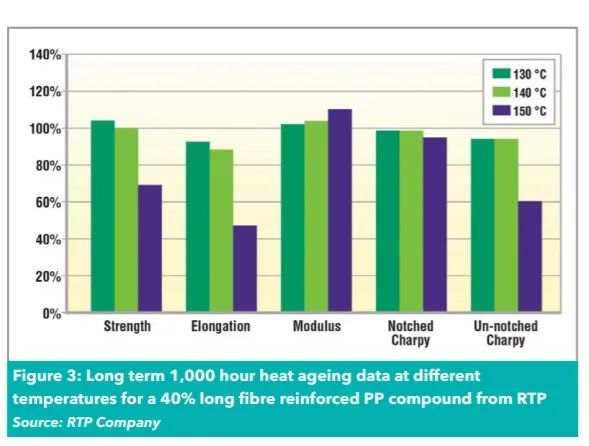

As the primary end user of LFT, the performance needs of the automotive industry are a key driver of LFT development. Current challenges include increasingly stringent VOC limits, the ability to withstand long-term thermal aging of more than 1,000 hours at 150°C (Figure 3), stronger UV-resistant linearity, and the ability to achieve A highly aesthetic Class A surface finish directly outside the mold. Usually several of these requirements need to be met in an application process.

Figure 3: Long-term 1,000-hour thermal aging data of 40% long fiber reinforced PP composites from RTP at various temperatures.

To address these automotive challenges, Xiamen LFT composite plastic Co.,ltd's product development team is constantly experimenting with extensive experimental combinations of new formulations, and developed anti - UV grade products.

Long fibre technology is now a mature area of the thermoplastic market. Nearly 40 years have passed since long fibre reinforced thermoplastics were first introduced in the early 1980s. So the industry is definitely at or reaching a stage of maturity, particularly in commodities for materials such as long glass fibre polypropylene, where it has a large number of suppliers. Most market research reports indicate that the long fiber materials market will continue to grow at a high single-digit CAGR for the foreseeable future. Growth has been prominent in the automotive industry, where long fibre materials are valued for their lightweight capabilities in metal replacement scenarios. The growth in material use has coincided with an increase in the global production of cars and trucks. Transportation is not the only market segment focusing on weight loss. Consumer discretionary products, especially sports and industrial equipment, are moving toward more portable devices that make life easier for users. While lightweight is often the first choice for product designers, the change to metal composites offers many other benefits. Cost reduction is a major driver, easily achieved when switching from metal manufacturing to injection molding production. The metal-like properties of long fiber composites, combined with their excellent durability, can also produce very strong products. These products are also usually made with recycling capabilities in mind. In a world increasingly concerned with the life cycle of materials, this is a necessary consideration.

LFT is valued for its lightweight and strength in applications such as off-road vehicles.