제품 번호: PA6-NA-LCF40

제품 섬유: 20%-60%

제품 적용 : 헬멧, 자동차 범프 및 로봇 및 팔 제조에 적합합니다.

제품 특징: 고인성, 경량, 고강도, 내마모성, 내식성, 내크리프성, 전도도, 열전달.

제품 번호: PA6-NA-LCF40

제품 섬유: 20%-60%

제품 적용 : 헬멧, 자동차 범프 및 로봇 및 팔 제조에 적합합니다.

제품 특징: 고인성, 경량, 고강도, 내마모성, 내식성, 내크리프성, 전도도, 열전달.

제품 번호.:

PA6-NA-LCF40지불:

T/T or L/C (other payment ways also can be di제품 원산지:

Xiamen, China색:

Original color (also can be customized)출하 항구:

Xiamen, ChinaProduct information

Nylon 6 (PA6) has the advantages of high mechanical strength, good toughness, excellent compressive performance, good fatigue resistance, creep resistance and so on. It can be used as the pressure material of non-metallic pipes to effectively prevent the deformation of non-metallic pipes and resist the external crushing of pipes.

Long Carbon fiber (LCF) has the characteristics of high strength, high modulus, large specific surface area and length-diameter ratio, and high conductivity, etc. By combining CF with PA6, the mechanical properties of PA6 can be further improved.

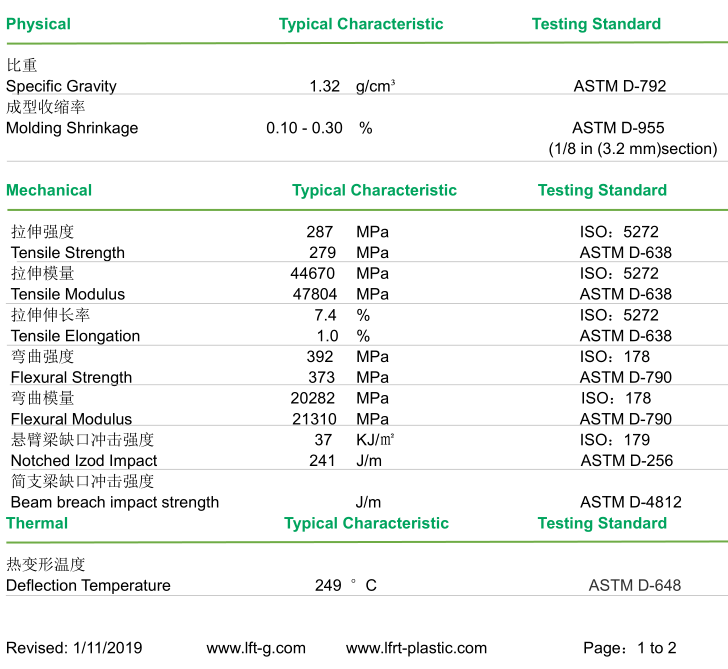

Product datasheet

The datasheet is made by our own lab, for reference only.

Product advantage

1. Light quality and high strength

The density of carbon fiber reinforced resin matrix composites commonly used in automobiles is 1.5 ~ 2.0g/cm3, only ordinary carbon steel 1/4 ~ 1/5, lighter than aluminum alloy about 1/3, and the mechanical properties of carbon fiber composites are better than metal materials, its tensile strength is 3 ~ 4 times higher than steel, stiffness is 2 ~ 3 times higher than steel, fatigue resistance is 2 times higher than steel. The weight is 3 ~ 4 times lighter than steel, and the coefficient of thermal expansion is 4 ~ 5 times smaller.

In terms of specific strength, carbon fiber composite is much stronger than carbon steel, and can exceed some special alloy steel, so it has a higher specific strength.

2. Good designability

The designability of carbon fiber composite is very strong, and it can be flexibly designed according to different application requirements. According to the stress condition of the product structure, the structure and arrangement of the fibers can be adjusted to make anisotropic and different thickness products, and the sandwich structure can be used to improve the overall rigidity of the components, so as to achieve the best lightweight design scheme.

By arranging the carbon fiber according to the force direction, the anisotropy of the strength of the composite can be brought into full play so as to save materials and reduce weight. However, due to the isotropy of metal materials, there will be excessive strength in the other direction after meeting the technical requirements of the maximum force direction.

For the products with corrosion resistance requirements, the matrix resin and reinforcement materials with good corrosion resistance can be selected in the design, while for some other performance requirements, such as dielectric properties, heat resistance, etc., can be met by choosing the appropriate raw materials. In addition, in order to make the product cost reach an acceptable degree, the replacement of low-cost materials can be appropriately selected, such as the mixed layup of different fibers, which can meet the component performance index and save the material cost.

3. Integration of parts

Composite material in the forming of its fluidity, easier to make a variety of shapes of the surface, to achieve an integrated molding effect. Therefore, composite materials are suitable for making automobile parts which are difficult to manufacture, low production efficiency and difficult to ensure accuracy.

For example, Lotus sports car aims to use carbon fiber material for the whole vehicle, and makes the body parts lightweight and integrated, which not only reduces the weight of the body, but also greatly increases the stiffness and strength of the parts and improves the performance of the whole vehicle.

4. Resistance to impact

The impact resistance of carbon fiber composites is also good. The carbon fiber composites based on polymer matrix have certain viscoelastic mechanical properties and can absorb certain impact energy.

5. 좋은 내식성

탄소 섬유 복합 제품은 일반적으로 녹 및 부식 문제가 없습니다. 폴리머 매트릭스 복합 재료는 내산성, 내해수성, 내알칼리성, 염분 및 유기용매성이 우수합니다. 따라서 내식성이 우수한 소재입니다 .

응용 프로그램 제품

초기 탄소 섬유 복합 재료는 주로 군대에서 사용되었습니다. 재료 특성의 향상, 성형 기술 및 가격 하락으로 인해 탄소 섬유 복합 재료는 일반 산업 및 스포츠 및 레저 분야에 점점 더 많이 적용되고 있습니다.

에너지 절약 및 환경 보호의 세계적인 추세에 따라 자동차 연료 소비 문제가 점점 더 많은 관심을 받고 있습니다. 경량 설계는 자동차 에너지 절약 및 배출 감소의 효과적인 방법이 되었으며 탄소 섬유 복합 재료의 재료 성능 및 개발 추세는 자동차 산업의 발전 요구와 일치합니다. 새로운 에너지 자동차의 개발로 인해 탄소 섬유 복합 재료는 자동차에서 점점 더 널리 사용될 것입니다.

게다가 헬멧, 자동차 범프 및 로봇 팔 등을 제조하는 데에도 적합합니다.

문의하기

Xiamen LFT composite Plastic Co., LTD.는 20년 동안 엔지니어링 플라스틱 수정을 전문으로 합니다. 신소재, 신기술, 소재 하나하나 정성스럽게 합니다. 우리 회사는 고객의 요구에 따라 재료를 사용자 정의할 수 있습니다. 20년 이상의 기술 경험 축적으로 신뢰할 수 있는 개질재 제조업체입니다. 문의에 오신 것을 환영합니다. 맞춤형 솔루션과 무료 견적을 제공할 수 있습니다!

이메일: sale02@lfrtplastic.com

연락처: 13950095727