-

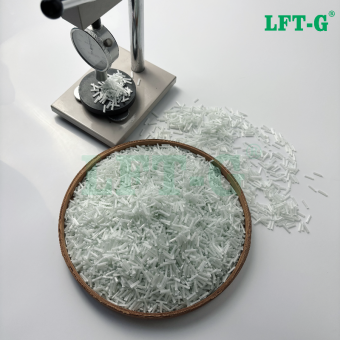

샤먼 LFT-G 고인성 MXD6 복합 충전 장유리섬유 원색나일론-MXD6는 m-벤조일아민과 아디프산의 축합으로 합성된 일종의 결정질 폴리아미드 수지입니다.

- 결정성 나일론 수지 mxd6 gf 좋은 가격

- 장유리섬유 mxd6 복합재료

- 고성능 플라스틱 mxd6

- 중국산 제품 화합물 mxd6

- 맞춤형 플라스틱 섬유 유리는 고강도 MXD6를 추가합니다.

- 열가소성 수지 열가소성 수지

태그 :

-

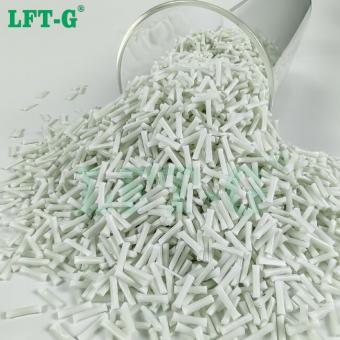

샤먼 LFT-G 폴리프로필렌 충전 장유리섬유 고성능 개질 플라스틱 12mmPP-LGF 유리섬유 강화 PP는 일반적으로 인장강도가 20~30MPa, 굽힘강도가 25~50MPa, 굽힘탄성률이 800~1500MPa입니다. PP를 엔지니어링 구조 부품에 사용하려면 유리섬유로 강화해야 합니다. 유리 섬유 강화 PP는 기계적 물성을 몇 배, 심지어 몇 배까지 향상시킬 수 있습니다. 구체적으로 인장 강도는 65MPa~90MPa, 굽힘 강도는 70MPa~120MPa, 굽힘 탄성률은 3000MPa~4500MPa에 달합니다. 이러한 기계적 강도는 ABS 및 강화 ABS 제품과 완전히 동일하며, 내열성도 더 뛰어납니다. 유리섬유 강화 PP, 일반 ABS 및 강화 ABS의 내열온도는 80℃~98℃이고, 유리섬유 강화 PP 소재의 내열온도는 135℃~145℃에 달할 수 있습니다. PP 충진 개질은 PP에 활석분, 탄산칼슘, 이산화티타늄, 운모 등과 같은 무기 미네랄을 일정량 첨가하여 강성, 내열성, 광택을 향상시키는 것입니다. 탄소 섬유, 붕소 섬유, 유리 섬유를 충진하면 인장 강도가 향상됩니다. 난연제를 첨가하면 난연성이 향상됩니다. 대전 방지제, 착색제, 분산제 등을 충진하면 대전 방지성, 착색성, 유동성 등이 향상됩니다. 핵제를 충진하면 결정화 속도가 빨라지고 결정화 온도가 상승하며, 더 많고 작은 구형 결정을 형성하여 투명성과 충격 강도를 향상시킵니다. 따라서 충진제는 플라스틱 제품의 성능 향상, 플라스틱 성형 가공성 향상, 비용 절감에 중요한 역할을 합니다. 애플리케이션 4대 일반 플라스틱 소재 중 하나인 PP는 종합 성능이 우수하고 화학적 안정성이 좋으며 성형성이 우수하고 가격이 비교적 저렴합니다. 그러나 강도, 탄성률, 경도가 낮고, 저온 충격 강도가 낮으며, 성형 수축이 발생하고, 노화가 쉬운 등의 단점이 있습니다. 따라서 제품 수요에 맞춰 개질해야 합니다. PP 소재의 개질은 일반적으로 무기물 강화, 내후성 개질, 유리 섬유 강화, 난연성 개질, 초강력 개질 등의 방법을 통해 이루어지며, 각 종류의 개질 PP는 가전제품 분야에서 다양한 용도로 활용됩니다. 유리 섬유 강화 PP는 냉장고, 에어컨, 냉동기(축류 팬, 횡류 팬 등) 제작에 사용될 수 있습니다. 또한, 고속 세탁기의 내부 드럼, 웨이브 휠, 벨트 휠 제작에도 사용되어 높은 기계적 특성 요건을 충족할 수 있으며, 밥솥 바닥 및 손잡이, 전자렌지 등 내열성이 요구되는 곳에 적합합니다. 유리 섬유 강화 PP. 일반적인 단섬유 강화 PP는 유리 섬유가 짧고 휘어지기 쉬우며, 충격 강도가 낮고 가열 시 변형되기 쉽습니다. 장섬유 강화 PP는 단섬유 강화 PP의 이러한 단점을 극복할 수 있으며, 표면 품질이 우수하고, 내열성이 우수하며, 충격 강도가 높아 냉장고 및 내열성이 높은 주방 가전제품에 사용할 수 있습니다. 유리섬유 강화 PP는 순수 PP를 기반으로 유리섬유와 기타 첨가제를 첨가하여 소재의 활용 범위를 넓힌 제품입니다. 일반적으로 대부분의 유리섬유 강화 소재는 제품의 구조 부품에 사용되는 구조 엔지니어링 소재입니다. 데이터시트 사례 샤먼 LFT 복합 플라스틱 유한회사 샤먼 LFT 복합 플라스틱 유한회사는 2009년에 설립되었으며, 제품 연구 개발(R&D), 생산 및 판매 마케팅을 통합하는 장섬유 강화 열가소성 소재의 세계적인 브랜드 공급업체입니다. 당사의 LFT 제품은 ISO9001&16949 시스템 인증을 획득했으며, 자동차, 군수 부품 및 총기, 항공우주, 신에너지, 의료 장비, 풍력 에너지, 스포츠 장비 등 다양한 분야에서 다수의 국가 상표 및 특허를 보유하고 있습니다.

- 장유리섬유 폴리프로필렌 고성능

- PP 사출 성형 복합재

- PP 수지 컴파운드 LFT GF

- 중국산 PP LGF LFT 열가소성 수지

- lgf 충전 pp 원료 샘플 제공

- PP 산업은 LFT 친환경 소재를 사용합니다

태그 :

-

LFT-G PA6 폴리아미드6 나일론6 충전재 장섬유 유리 40가지 색상 (자동차 부품용)PA6 및 PA6-LGF 장섬유 강화 나일론 PA6, also known as Nylon 6, is a high-performance polyamide widely used in engineering plastics, fibers, and films. It is a thermoplastic polymer with repeating amide groups (-NH-CO-) in the main chain, offering strong mechanical properties and versatile processing capabilities. What is PA6 Plastic? PA6 is an aliphatic polyamide that provides excellent strength, wear resistance, and chemical resistance to weak acids, alkalis, and certain organic solvents. Its lightweight and processable nature make it widely applied in fibers, engineering plastics, and thin films. However, the polar amide groups in PA6 easily form hydrogen bonds with water molecules, which can result in high moisture absorption, dimensional changes, and reduced impact strength in dry or low-temperature conditions. Advantages of PA6 High mechanical strength and toughness with excellent tensile and compressive properties Outstanding fatigue resistance, maintaining strength after repeated bending High softening point, heat resistant Low friction and wear-resistant surface Corrosion resistance to alkalis, salts, weak acids, oils, and most solvents Self-extinguishing, non-toxic, odorless, and good weather and biological resistance Excellent electrical insulation even in high humidity environments Lightweight, easy to dye, and easy to mold due to low melting viscosity Limitations of PA6 High moisture absorption (up to 3% when saturated) Poor light and thermal stability; prolonged high-temperature exposure may cause discoloration and surface cracking Strict injection molding requirements; trace moisture can affect product quality Dimensional stability is sensitive to thermal expansion and wall thickness variations Not resistant to strong acids or oxidizing agents; unsuitable for acid-resistant applications Why Reinforce PA6 with Long Glass Fiber? To overcome the natural limitations of PA6, long glass fiber (LGF) reinforcement is applied. PA6-LGF composites combine the lightweight, chemical, and heat resistance of PA6 with the mechanical strength and dimensional stability of long glass fibers. LGF reinforcement improves tensile, compressive, and flexural strength, reduces shrinkage, enhances fatigue resistance, and provides improved thermal and chemical stability. This makes PA6-LGF ideal for high-performance structural components. Applications of PA6-LGF PA6 reinforced with 30% long glass fiber (30% LGF) is widely used in: Power tool shells and components Engineering machinery parts Automobile structural and functional components The composite improves mechanical strength, dimensional stability, heat resistance, aging resistance, and fatigue resistance. Its fatigue strength can be up to 2.5x that of unreinforced PA6. Processing and Forming Tips for 30% PA6-LGF Shrinkage is reduced to ~0.3% compared with 1–1.5% for pure PA6. Excessive fiber content may cause surface floating fibers and poor compatibility. 30% LGF is recommended for balanced performance. Recycled material content should be kept below 25% to avoid color and mechanical property degradation. Gradual cooling after molding prevents warping due to fiber orientation during injection molding. Mold design, gate position, and temperature control are critical. Customers & Staffs Certificates더보기

-

LFT-G는 변성 나일론66, PA66, 장섬유 유리 복합재를 전자 기기에 충전하는 데 사용됩니다.PA66-LGF 장섬유 강화 나일론 PA66, or Nylon 66, is a high-performance polyamide widely used in engineering plastics. It offers excellent mechanical properties including tensile strength, flexural strength, and impact resistance, along with superior thermal and chemical stability. With lightweight, high wear resistance, good electrical insulation, and self-extinguishing properties, PA66 is ideal for automotive, electrical, industrial equipment, and construction applications. Why Reinforce PA66 with Long Glass Fiber? While PA66 is versatile, it has limitations: high water absorption, low compressive strength when wet, poor alkali resistance, and potential deformation at ultra-low temperatures. Long glass fiber (LGF) reinforcement addresses these challenges. Adding LGF significantly improves impact resistance, thermal deformation resistance, mechanical performance, molding processability, and chemical resistance. LGF acts as a robust internal skeleton, enhancing the durability and reliability of PA66 components. PA66-LGF Technical Datasheet *The datasheet is tested by Xiamen LFT and provided for reference only.* Applications of PA66-LGF PA66 reinforced with 30% long glass fiber is ideal for high-performance applications such as: Automotive components and structural parts Power tool housings and mechanical parts Industrial equipment components For specialized applications, please consult our technical team. PA66-LGF Product Details Number Color Length Sample MOQ Port of Loading Delivery Time Payment Terms PA66-NA-LGF30 Original color (customizable) 12mm (customizable) Available 25kg Xiamen Port 7-15 days after shipment Discussed Xiamen LFT Composite Plastic Co., Ltd Xiamen LFT Composite Plastic Co., Ltd. is a leading manufacturer specializing in long fiber reinforced thermoplastics (LFT & LFRT), including Long Glass Fiber (LGF) and Long Carbon Fiber (LCF) series. Our thermoplastic LFT can be applied in LFT-G injection molding, extrusion molding, and LFT-D molding. We provide products according to customer requirements with fiber lengths from 5 to 25mm. Our continuous infiltration reinforced thermoplastics have passed ISO9001 & 16949 certifications and hold numerous national patents and trademarks. Our Services Technical parameters and leading-edge design of LFT & LFRT materials Mold front design recommendations Technical support for injection molding and extrusion molding processes

- 저변형 전자제품

- 자체 소유 pa66 펠릿

- 고강도 및 고인성 강화 PA66 펠릿

- 최고 품질의 장섬유 유리 PA66 LGF30 과립

- PA66 6 트윈 스크류 lgf 펠릿

- 장섬유 PA66 과립의 응용 분야

태그 :

-

PLA(폴리락트산) 화합물, 긴 유리섬유 열가소성 수지 (엔지니어링용)PLA 및 LGFLA – 친환경 강화 바이오플라스틱 PLA (Polylactic Acid) is a non-natural polyester and one of the most promising "green plastics." Known for its biocompatibility, biodegradability, and high mechanical strength, PLA can be completely degraded by microorganisms into CO₂ and water, making it non-toxic and environmentally friendly. PLA offers mechanical properties similar to polypropylene, while providing the gloss, clarity, and processability of polystyrene. With a lower processing temperature than polyolefins, PLA can be molded via injection molding, extrusion, blow molding, spinning, and other general plastic processes. Its applications range from disposable packaging and fibers to nonwovens, and extend to medical, chemical, pharmaceutical, and 3D printing industries. Long Glass Fiber Reinforced PLA (LGFPLA) Glass fiber is an inorganic non-metallic material with excellent insulation, heat resistance, corrosion resistance, and mechanical strength. When used to reinforce PLA, it creates Long Glass Fiber PLA (LGFPLA), a high-performance thermoplastic composite with glass fibers 10–25mm long, forming a 3D structure for superior strength and stability. LGFPLA is available as columnar pellets, typically 12mm (for injection molding) or 25mm (for compression molding) in length, with glass fiber content from 20% to 60%. Colors can be customized to match client requirements. Advantages of LGF vs SGF (Long Fiber vs Short Fiber PLA) Longer fiber length improves mechanical properties and part durability. High specific stiffness and strength, with excellent impact resistance — ideal for automotive parts. Improved creep resistance and dimensional stability for precise molding. Outstanding fatigue resistance and long-term reliability. Stable performance in high temperature and humid environments. Minimal fiber damage during molding due to fiber mobility within the mold. Technical Specifications Product Number Color Length Fiber Specification Package Sample Port of Loading Delivery Time PLA-NA-LGF Natural or customizable 6–25mm 20%–60% 25kg/bag Available Xiamen Port 7–15 days after shipment Lab & Factory Xiamen LFT Composite Plastic Co., Ltd. Xiamen LFT Composite Plastic Co., Ltd. specializes in developing and producing long glass fiber (LGF) and long carbon fiber (LCF) reinforced thermoplastic composites (LFT-G, LFRT, LFT). Our materials are lightweight, high-strength, impact-resistant, and environmentally friendly, offering excellent corrosion and chemical resistance along with superior molding performance. Our products are used across industries including automotive, aerospace, military, electrical, medical, sports equipment, and daily consumer goods, producing components such as gears, rollers, pulleys, pump impellers, fan blades, and more.

- PLA 강화 플라스틱 LGF 생산 PLA

- LFT-G PLA 사출 성형용 개량 소재

- 긴 유리 섬유 복합 PLA 수지 기본

- 중국산 장섬유 PLA 펠릿 30

- PLA 폴리머 제조업체 자체 소유, 직판

- PLA 순수 펠릿 버진 그레이드 lft

태그 :

-

LFT-G 산업용 HDPE 충전재 LGF 30~60% 고강도 펠릿 12mm 무료 샘플고밀도 폴리에틸렌(HDPE) 플라스틱 | 장섬유 유리 강화 고밀도 폴리에틸렌(HDPE) HDPE란 무엇인가요? 고밀도 폴리에틸렌(HDPE)은 무독성, 무취의 고결정성(80%~90%) 열가소성 과립 소재입니다. 연화점은 125~135°C이며 최대 100°C의 온도에서 사용할 수 있습니다. 저밀도 폴리에틸렌(LDPE)과 비교했을 때, HDPE는 경도, 인장 강도, 크리프 저항성, 내마모성, 전기 절연성, 인성 및 내한성이 우수합니다. 또한 상온에서 모든 유기 용매에 불용성이며 산, 알칼리 및 다양한 염류에 대한 내식성이 뛰어나 화학적 안정성이 우수합니다. 장섬유 유리 강화 플라스틱(LGF) 장섬유 유리 강화 플라스틱(LGF 플라스틱)은 유리 섬유를 첨가하여 만들어집니다. 긴 유리 섬유 LGF 플라스틱은 순수 플라스틱에 다른 첨가제를 넣어 강화할 수 있습니다. 이러한 강화는 재료의 기계적 및 열적 특성을 크게 향상시켜 구조 및 엔지니어링 분야에 적합하게 만듭니다. LGF 플라스틱은 PP, ABS, PA66, PA6, HDPE, PPA, TPU, PEEK, PBT, PPS 등의 재료와 함께 일반적으로 사용됩니다. 장섬유 유리 강화 플라스틱의 장점 내열성 향상: 유리 섬유는 플라스틱, 특히 나일론 기반 소재의 고온 성능을 향상시킵니다. 수축률 감소 및 강성 증가: 섬유 보강재가 고분자 사슬의 움직임을 제한하여 치수 안정성을 향상시킵니다. 향상된 충격 저항성: 강화 플라스틱은 응력 균열에 강하고 인성이 더 높습니다. 강도 향상: 고강도 유리 섬유 덕분에 인장, 압축 및 굽힘 강도가 크게 향상되었습니다. 난연성: 섬유 및 첨가제를 첨가하면 가연성이 감소하여 대부분의 강화 플라스틱이 불연성이 됩니다. HDPE/LGF 데이터시트 문의하기 더 자세한 정보는 다음을 참조하세요. HDPE 플라스틱 그리고 긴 유리 섬유 강화 HDPE 자재 관련 문의는 당사 영업팀으로 연락해 주십시오. 당사는 산업 및 엔지니어링 분야에 필요한 기술 지원, 맞춤형 솔루션 및 샘플 요청을 제공합니다.

- HDPE 충전재, 긴 유리 섬유, 흰색

- LGF를 함유한 고성능 HDPE

- 사출 성형 플라스틱 HDPE 버진

- 원색 10-12mm HDPE 펠릿 폴리머 수지

- 엔지니어링 플라스틱은 HDPE로 재활용할 수 있습니다.

- 고강성 열가소성 화합물 HDPE

태그 :

-

MXD6 충전재, 장섬유 유리 30 고인성 사출 성형, 천연색 샘플 제공 가능MXD6 플라스틱 | 장섬유 유리 강화 MXD6 (MXD6-LGF) MXD6는 무엇인가요? 폴리아디필-m-벤조일아민은 일반적으로 다음과 같이 불립니다. MXD6 또는 나일론 MXD6 MXD6는 고성능 엔지니어링 열가소성 수지입니다. 다른 엔지니어링 플라스틱에 비해 기계적 강도와 탄성률이 높습니다. 또한 산소와 이산화탄소에 대한 저항성이 뛰어난 특수 고차단성 나일론입니다. PVDC나 EVOH와 달리 온도나 습도의 영향을 받지 않아 고온다습한 환경에 이상적입니다. 구조 및 기계적 성능 MXD6 나일론은 높은 강도, 높은 강성, 높은 열변형 온도, 낮은 열팽창률, 우수한 치수 안정성 및 낮은 흡수율을 나타냅니다. 또한, 수분 흡수 후에도 기계적 특성 변화가 최소화됩니다. MXD6는 수축률이 낮아 정밀 성형에 적합하고, 고온에서도 우수한 도장성을 가지며, 탁월한 차단성을 제공합니다. MXD6의 장점 넓은 온도 범위에서 높은 강도와 강성을 유지합니다. 높은 열변형 온도와 낮은 열팽창 계수 낮은 수분 흡수율과 최소한의 기계적 특성 저하 성형 수축률이 작아 정밀 성형 공정에 적합합니다. 특히 고온에서 도장성이 매우 우수합니다. 산소, 이산화탄소 및 기타 가스에 대한 탁월한 차단 성능 MXD6-LGF | 장섬유 강화 MXD6 MXD6는 긴 유리 섬유, 탄소 섬유, 광물 및 고급 충전재와 혼합하여 50~60%의 유리 섬유 강화 복합재를 생산할 수 있습니다. 그 결과 탁월한 강도와 강성을 유지하면서도 도장, 금속 코팅 또는 반사 하우징에 이상적인 매끄럽고 수지 함량이 높은 표면을 얻을 수 있습니다. MXD6-LGF의 주요 장점 얇은 벽에 적합한 높은 유동성: 유리섬유 함량이 60%에 달하더라도 두께가 0.5mm에 불과한 벽도 채울 수 있습니다. 뛰어난 표면 마감: 수지 함량이 높은 표면은 섬유 함량이 높음에도 불구하고 높은 광택을 제공합니다. 매우 높은 강도와 강성: 50~60%의 유리 섬유를 함유한 많은 주조 금속 및 합금과 유사합니다. 우수한 치수 안정성: 수축률이 낮고 공차가 엄격하며, 선팽창 계수는 여러 금속과 유사합니다. MXD6-LGF TDS (기술 데이터 시트) MXD6-LGF의 응용 분야 MXD6-LGF MXD6는 자동차, 전자제품 및 가전제품의 고품질 구조 부품에 사용되는 금속 대체재입니다. 높은 기계적 강도와 내유성이 요구되는 환경에서 우수한 성능을 발휘하며, 120~160℃의 고온에서 장기간 사용 가능합니다. 유리섬유 강화 소재인 MXD6는 최대 225℃의 내열성을 유지하여 자동차 엔진의 실린더 블록, 실린더 헤드, 피스톤 및 동기 기어에 적합합니다. MXD6/PPO 합금은 고온 저항성, 고강도, 내마모성, 내유성 및 탁월한 치수 안정성을 제공하여 자동차 차체 패널, 펜더, 휠 커버 및 복잡한 곡선 부품의 금속 대체재로 사용될 수 있습니다. 회사 소개더보기

-

샤먼 LFT-G PLA 폴리락트산 복합재 장유리섬유 강화 열가소성 수지 원색PLA 플라스틱 | 장섬유 유리 강화 PLA (PLA-LGF) PLA란 무엇인가요? 폴리락트산( 인민해방군 PLA는 생분해성 및 친환경 고분자 플라스틱으로, 무공해 공정을 통해 생산됩니다. PLA는 환경에서 자연적으로 분해되고 재활용될 수 있어 이상적인 친환경 고분자 소재이자 가장 대표적인 생분해성 플라스틱 중 하나입니다. PLA 구조 및 내열성 PLA의 분자 구조는 내열성, 인성, 기계적 강도, 분해성 및 생체 적합성에 영향을 미칩니다. PLA는 활성이 낮은 나선형 분자 사슬을 가지고 있어 사출 성형 후 결정화 속도가 느리고 내열성이 상대적으로 떨어집니다. 고온 가공 과정에서 에스테르 결합이 부분적으로 끊어져 말단 카르복실기가 생성될 수 있으며, 이는 열 분해를 가속화합니다. 장섬유 유리(LGF) 강화 PLA 긴 유리 섬유로 PLA를 강화하기 PLA-LGF ) 기계적 강도, 강성 및 내열성을 향상시킵니다. 섬유는 골격 지지대 역할을 하여 가열 중 고분자 사슬의 움직임을 제한하고 열 안정성을 높입니다. PLA 보강재용 섬유 종류 PLA 강화에 사용되는 섬유는 다음과 같습니다. 천연 식물 섬유: 사이잘, 아마, 리넨, 대나무, 코코넛, 목재 섬유 동물성 섬유: 실크 광물 섬유: 현무암 섬유 화학 섬유: 유리 섬유, 탄소 섬유 유리섬유와 탄소섬유는 높은 강도와 탄성률 때문에 널리 사용되는 반면, 천연섬유는 생분해성과 재생 가능한 자원이라는 장점 때문에 선호됩니다. PLA와 혼합된 변성 섬유는 140°C를 초과하는 비카트 연화 온도를 나타냈습니다. 단섬유(SGF)와 비교했을 때 장섬유 유리 강화 PLA는 단섬유(SGF) 유리 강화 PLA에 비해 우수한 기계적 특성을 나타냅니다. 인성은 1~3배, 인장 강도 및 강성은 0.5~1배 더 높아 대형 구조 부품에 더욱 적합합니다. PLA-LGF 사출 성형 실험실 및 테스트 창고 및 보관 인증 샤먼 LFT 복합 플라스틱 유한회사 소개 샤먼 LFT 복합 플라스틱 유한회사는 장섬유 강화 열가소성 수지(LFT)를 전문으로 생산하며, 여기에는 다음이 포함됩니다. 인민해방군

- PLA 복합 플라스틱은 재활용이 가능합니다.

- 폴리락트산 소재 사출 성형

- 변형된 PLA 화합물

- PLA(장섬유 강화 플라스틱 수지)

- 긴 유리 섬유 충전 PLA 샘플을 구할 수 있습니다.

- lft-g pla lgf 낮은 뒤틀림

태그 :

-

고강도 PA12 나일론12 복합재(LGF) 순수 백색 자동차용제품 번호: PA12-NA-LGF 광섬유 규격: 20%-60% 제품 특징: 높은 강도, 뛰어난 인성 및 내구성 제품 적용 분야: 자동차, 스포츠 부품, 태양 에너지, 태양광 산업 및 기타 산업에 적합합니다.

- 나일론12 충전재가 들어간 장섬유 강화 플라스틱

- 내구성이 뛰어나고 기계적 특성이 우수합니다.

- 태양광 산업 단지

- 사출 성형용 열가소성 수지

- 24시간 서비스, 금속 대신 플라스틱으로 맞춤 제작 가능

- 공급업체 가격 좋은 가격 pa6 복합재

태그 :

-

LFT-G PPS 폴리페닐렌 설파이드 LGF 복합재 장유리섬유 맞춤형 엔지니어링 플라스틱PPS 및 PPS-LGF | 고성능 엔지니어링 플라스틱 PPS란 무엇인가요? 폴리페닐렌 설파이드(PPS)는 우수한 내열성, 화학적 안정성, 난연성 및 기계적 강도를 지닌 고성능 엔지니어링 열가소성 수지입니다. PPS는 보강 및 개질을 통해 물리적, 기계적 및 전기적 특성의 균형 잡힌 조합을 제공합니다. PPS는 뛰어난 치수 안정성, 내식성 및 전기 절연 성능을 갖추고 있어 열악한 산업 환경에 적합합니다. PPS의 주요 특징 뛰어난 고온 저항성 높은 경도와 내마모성 장기간 하중 조건에서도 우수한 크리프 저항성을 보입니다. 넓은 온도 범위에서 뛰어난 전기적 특성을 나타냅니다. 기계적 특성의 온도 변화에 대한 민감도가 낮음 변형되지 않은 PPS는 본래 취성이 강하고 충격 강도가 비교적 낮습니다. 이러한 한계는 섬유 보강 및 재료 변형을 통해 효과적으로 극복할 수 있습니다. PPS-LGF란 무엇인가요? PPS-LGF는 장유리섬유로 강화된 폴리페닐렌 설파이드를 의미합니다. 엔지니어링 플라스틱 중에서 PPS-LGF는 뛰어난 내열성, 구조적 강도 및 장기적인 신뢰성으로 두각을 나타냅니다. 열변형 온도(HDT) 이상 260°C 내화학성은 PTFE 다음으로 우수합니다. 성형 수축률이 낮고 수분 흡수율이 극히 낮습니다. 뛰어난 난연성 및 진동 피로 저항성 높은 습도와 고온 환경에서도 뛰어난 전기 절연 성능을 제공합니다. 긴 유리 섬유를 첨가함으로써 PPS-LGF는 인성과 충격 강도를 크게 향상시켜 순수 PPS의 취성을 극복하고 탁월한 종합 성능을 제공합니다. PPS-LGF는 다양한 응용 분야에서 스테인리스강, 구리, 알루미늄 및 합금과 같은 금속을 대체할 수 있으므로 금속 대체 및 경량 설계에 이상적인 소재입니다. 이미지 자리 표시자 PPS-LGF의 응용 분야 PPS-LGF는 높은 강도, 내열성 및 화학적 안정성이 요구되는 산업 분야에서 널리 사용됩니다. 예를 들면 다음과 같습니다. 자동차 부품 항공우주 구조물 가전제품 기계 및 구조 부품 화학 처리 장비 전기 절연 및 내식성 부품 제품 상세 정보 등급 색상 펠릿 길이 최소 주문 수량 포장 견본 배송 시간 선적항 PPS-NA-LGF30 내추럴(맞춤 설정 가능) ≥ 5–25 mm 25kg 25kg/포대 사용 가능 배송 후 7~15일 샤먼항 생산 공정 당사의 PPS-LGF 소재는 첨단 장섬유 함침 기술을 사용하여 생산되므로 섬유 길이 유지율이 우수하고, 균일하게 분산되며, 기계적 성능이 안정적입니다. 상표 및 특허 당사의 제품은 일관된 품질과 안정적인 성능을 보장하기 위해 독자적인 기술, 등록 상표 및 특허 공정으로 뒷받침됩니다. 팀과 고객 숙련된 연구 개발 및 생산팀의 지원을 받는 당사의 PPS-LGF 소재는 자동차, 산업 및 전기 분야를 포함한 전 세계 고객들에게 신뢰를 받고 있습니다. 저희가 제공하는 것 LFT 및 LFRT 소재 기술 데이터 및 고급 설계 지원 금형 전면 설계 권장 사항 및 최적화 사출 성형 및 압출 가공에 대한 전문적인 기술 지원을 제공합니다.더보기

이메일

이메일 한국의

한국의 English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 中文

中文