제품 번호.:

MXD6-NA-LGF30지불:

T/T or L/C (other payment ways also can be di제품 원산지:

Xiamen, China색:

Original color (also can be customized)출하 항구:

Xiamen, ChinaMXD6

Polyadipyl-m-benzoylamine, referred to as mxd6, generally referred to as "nylon mxd6", resin than other engineering plastics have higher mechanical strength and modulus, is also a special high barrier nylon material. Although the barrier of mxd6 is slightly worse than that of pvdc and evoh, its barrier is not affected by temperature and humidity, which is especially suitable for high temperature and humid occasions. In today's barrier packaging and plastic instead of steel general trend, nylon mxd6 has become one of the most eye-catching new plastic varieties.

Structure performance: PA MXD6 nylon material has high strength, high rigidity, high thermal deformation temperature, small thermal expansion coefficient; Dimensional stability, low water absorption rate and small size change after water absorption, mechanical strength changes less; Forming shrinkage is small, suitable for precision forming processing; Excellent coating performance, especially suitable for high temperature surface coating; Excellent barrier to oxygen, carbon dioxide and other gases. Excellent mechanical and thermal properties and high strength, high modulus and heat resistance, high barrier, excellent cooking resistance

Advantages

1、Maintain high strength and rigidity in a wide temperature range

2、High heat deflection temperature, small coefficient of thermal expansion

3、Low water absorption, small size change after water absorption, less mechanical strength reduction

4、Small shrinkage rate of molding, suitable for precision molding process

5、Excellent paintability, especially suitable for surface painting under high temperature

6、Excellent barrier to oxygen, carbon dioxide and other gases

MXD6-LGF

MXD6 applications in the plastics modification industry

MXD6 can be compounded with glass fibers, carbon fibers, minerals and/or advanced fillers for materials containing 50-60% glass fiber reinforcement with exceptional strength and stiffness.

Even when filled with high levels of glass fiber, its smooth, resin-rich surface creates a high gloss finish like no glass fiber, making it ideal for painting, metal coating or creating naturally reflective housings.

1、High fluidity for thin wall

It is a very high flowing resin that can easily fill thin walls as thin as 0.5 mm thick even with glass fiber content as high as 60%.

2、Excellent surface finish

The resin-rich perfect surface has a highly polished appearance, even with a high glass fiber content.

3、Very high strength and stiffness

MXD6 with 50-60% glass fiber reinforcement has a tensile and flexural strength similar to many cast metals and alloys.

4、Good dimensional stability

At ambient temperature, the coefficient of linear expansion (CLTE) of MXD6 glass fiber composite is similar to that of many cast metals and alloys. It is highly reproducible due to low shrinkage and the ability to maintain tight tolerances (length tolerances can be as low as ± 0.05% if properly formed).

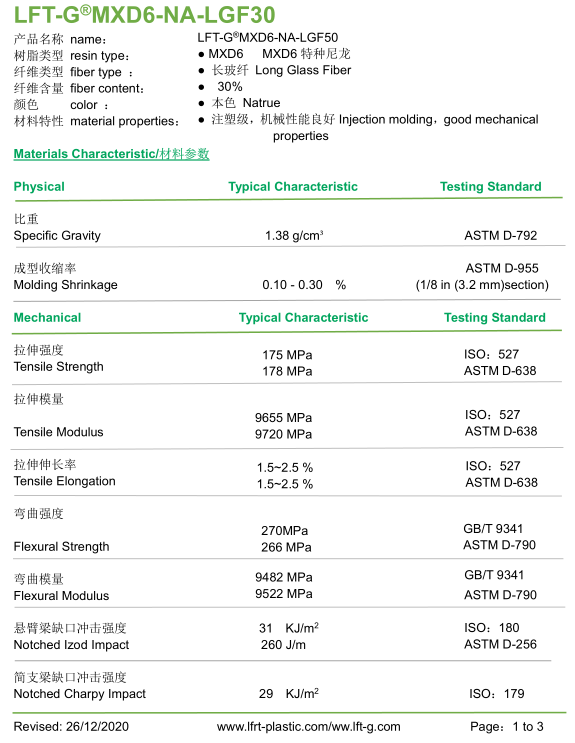

참조용 TDS

애플리케이션

MXD6는 금속을 대체하여 자동차, 전자 제품 및 전기 제품의 고품질 구조 부품을 만듭니다.

자동차 부품에서는 기계적 강도가 높고 내유성이 좋은 소재 제품이 필요한 경우가 많으며 120~160℃ 범위에서 장기간 사용할 수 있습니다. 유리섬유가 강화된 MXD6는 225℃까지의 내열성과 고온에서 높은 강도 유지율을 가지고 있어 자동차 엔진의 실린더 블록, 실린더 헤드, 피스톤, 동기 기어 등에 사용할 수 있습니다. MXD6/PPO 합금은 고온 저항, 고강도, 내유성, 내마모성, 우수한 치수 안정성 등의 특성을 가지고 있습니다. 자동차 차체의 수직 외부 패널, 앞뒤 펜더, 휠 커버에 사용할 수 있으며 스탬핑 및 성형이 거의 불가능합니다. 강판. 자동차의 곡선 부품 및 섀시.

회사 소개