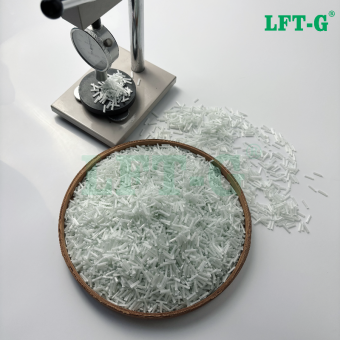

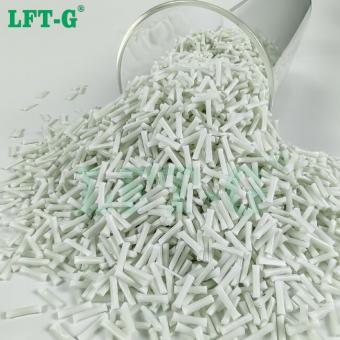

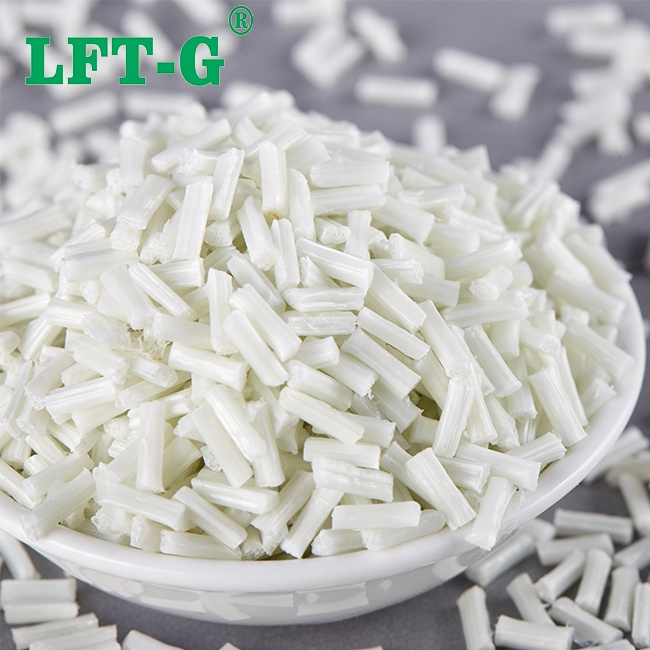

√ The first lightweight third row freestanding seat back √ Solution helps new cars lose 30% weight and save 15% cost over their predecessor Lightweight parts have been successfully applied and applied to the new 2021 cars. The new model, due to go on sale in the second half of this year, has managed to reduce body weight with a lightweight component on the back of the third-row chair. The third-row back of the previous generation of cars was made up of 15 different steel components, and the body was very heavy. So hopefully the 2021 third row seats will meet all performance criteria while being lighter and more cost competitive. "Being lighter does not necessarily mean being more expensive," the researchers said. Compared with the previous generation model, during the research and development of the new model, we not only achieved a 30% reduction in the weight of the third row seat, but also saved 15% of the cost. These goals are achieved because we have many great partners." The resin parts of traditional car seats contain metal reinforcement, which increases the cost of the process. The hope is to obtain a whole injection parts without complex, expensive processing. To meet the requirements, an exclusive 35% fiberglass reinforced, impact-resistant modified polyamide PA6 product was used along with its proprietary computer simulation (CAE) tool that can be used in multiple stages of development. 개발자는 바스프의 독점 컴퓨터 시뮬레이션(CAE) 도구에 대해 "2021년형 토요타 세나의 3열 시트 디자인을 구현 기술로 분류한다"고 말했다. 인서트 없이 설계된 최초의 완전 사출 성형 시트 등받이이며 설계 과제 중 하나는 충돌 방지 요구 사항을 충족하기 위해 시트가 높은 연신율과 내충격성을 갖도록 하는 것이었습니다. "동시에 우리는 3열도 바닥을 지지하기 때문에 시트의 강도와 강성에 중점을 두었습니다." 저희에게 연락 주시면 최고의 가격으로 최고의 재료를 제공해 드리겠습니다.

더보기

이메일

이메일 한국의

한국의 English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 中文

中文